Raniganj, Bardhaman, West Bengal

- GST NO. : 19ADIPB5886A1ZL

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Size | as per use |

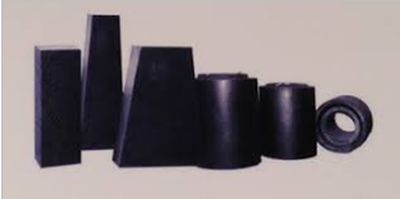

| Type | Magnesia Carbon Brick, Bricks |

| Material | Magnesia Carbon |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Shape

Rectangular, Square, As Per Use

Application

Industrial Use

Color

Black

Structure

Solid

Resistance Durability

Heat Resistance

Certification

ISI Certified

Product Code

MgOC

Port

Kolkata

Payment Terms

L/C, T/T, Other

Delivery Time

1 Month

Packaging Details

Export Packing

We are a reliable Importer and Supplier of MAG Carbon Bricks for Converter/ EAF /Ladle. The MAG Carbon Bricks for Converter/ EAF /Ladle that we bring to you is made up of top-notch quality raw materials and sophisticated machines.

Specifications

| i) Resin Bonded Bricks for converter | ||||||||||

| MGO % | MGO (Loss Free Basis) % (Min) | FC % (Min) | AL2O3% (Max) |

A.P. % (Max) | BD gm/cc (Min) | C.C.S Kg/cm2 (Min) | HMOR Kg/cm2 @ 1400 oC (Min) |

Application Area | ||

| 97 | 84 | 12 | 3 | 2.8 | 3 | 450 | 120 | Bottom Lower Case | ||

| 97 | 84 | 12 | 3 | 2.8 | 3 | 450 | 120 | Lower Cone | ||

| 97 | 84 | 12 | 3 | 2.8 | 3 | 450 | 120 | Barrel | ||

| 97 | 84 | 12 | 3 | 2.8 | 3 | 450 | 120 | Top Cone | ||

| 97 | 87 | 9 | 3 | 2.8 | 3 | 450 | 120 | Charge Paid | ||

| 97 | 80 | 15 | 3 | 2.8 | 3 | 450 | 120 | Trunion | ||

| 97 | 81 | 13 | 3 | 2.8 | 3 | 450 | 120 | Tap Hole | ||

| ii) Pitch Bonded bricks for converter | ||||||||||

| 98 | 90 | 5 | 2.98 | 4- | 480- | 80 | Hot & Cold Spots | |||

| 96 | 85 | 10 | 2.97 | 4- | 420- | 80 | ||||

| 96 | 82 | 13 | 2.96 | 4- | 400- | 80 | ||||

| 93 | 80 | 15 | 2.95 | 4- | 400- | 80 | ||||

| Typical & Average data of Magnesia Carbon Bricks for EAF/UHPF Furnace | |||||||||

| MGO % (Min) | MGO Loss Free % (Min) | FC % (Min) | BD gm/cc (Min) | A.P. % (Max) | Coked A.P. @ 1000oC % (Max) |

CCS Kg/ cm2 (Min) | MOR Kg/cm2 @ room temp |

HMOR Kg/ cm2 @ 1400oC (Min) |

Area of Application |

| 97 | 86 | 12 | 2.98 | 3 | 11 | 420 | 140 | 120 | Hot Spots |

| 97 | 84 | 14 | 2.96 | 3 | 12 | 400 | 140 | 120 | |

| 97 | 81 | 16 | 2.9 | 2.8 | 13 | 400 | 140 | 120 | |

| 98 | 87 | 12 | 2.98 | 3 | 11 | 450 | 110 | 80 | Hot & Cold Spots |

| 98 | 85 | 14 | 2.96 | 3 | 12 | 420 | 110 | 80 | |

| 98 | 82 | 16 | 2.9 | 2.8 | 13 | 400 | 110 | 80 | |

| 96 | 85 | 12 | 2.98 | 4 | 11 | 420 | 90 | 60 | Cold Spots |

| 96 | 84 | 14 | 2.96 | 4 | 12 | 400 | 90 | 60 | |

| 96 | 81 | 16 | 2.9 | 4 | 13 | 400 | 90 | 60 | |

| Typical and Average Data of Magnesia Carbon Bricks for Ladle | ||||||||||

| MGO % (Min) | MGO Loss Free % (Min) | FC % (Min) | BD gm/cc (Min) | A.P. % (Max) | Coked A.P @ 1000oC % (Max) |

CCS Kg/ cm2 (Min) | MOR Kg/cm2 @ room temp. |

HMOR Kg/ cm2 @ 1400 oC (Min) |

Area of Application | |

| 98 | 90 | 5 | 3 | 3 | 10 | 480 | 160 | 90 | Bottom & Metal Zone | |

| 98 | 88 | 8 | 2.99 | 3 | 10 | 450 | 150 | 90 | -“- | |

| 98 | 86 | 10 | 2.99 | 2.8 | 10 | 400 | 140 | 90 | Slag Zone | |

| 98 | 84 | 12 | 2.92 | 2.8 | 11 | 400 | 140 | 90 | - “ - | |

| 96 | 89 | 5 | 3 | 4 | 10 | 480 | 140 | 80 | Bottom & Metal Zone | |

| 96 | 87 | 8 | 2.98 | 4 | 10 | 450 | 120 | 80 | - “ - | |

| 96 | 85 | 10 | 2.95 | 4 | 10 | 400 | 110 | 80 | Slag Zone | |

| 96 | 83 | 12 | 2.9 | 4 | 11 | 400 | 110 | 90 | - “ - | |

| 95 | 5 | 88 | 2.98 | 4 | 10 | 400 | 110 | 60 | Bottom & Metal Zone | |

| 95 | 86 | 8 | 2.98 | 4 | 10 | 400 | 110 | 60 | - “ - | |

| 95 | 84 | 10 | 2.95 | 4 | 10 | 400 | 110 | 60 | Slag Zone | |

| 95 | 82 | 12 | 2.9 | 4 | 11 | 400 | 100 | 60 | - “ - | |

| 93 | 83 | 8 | 2.85 | 6 | 1A | 400 | 100 | 50 | Free Board & Low Temp Applications | |

| 92 | 82 | 8 | 2.85 | 6 | 1A | 350 | 90 | 50 | -- | |

| 90 | 81 | 8 | 2.85 | 7 | 14 | 300 | 100 | 50 | -- | |

Looking for "Magnesia Carbon Bricks" ?

Ton

Explore More Products

Our Blogs