Raniganj, Bardhaman, West Bengal

- GST NO. : 19ADIPB5886A1ZL

Refractories

Leading Manufacturers, Exporters, Wholesaler, Trader and Importer of High Alumina Bricks, Refractory Firebrick, Castables, Refractories Grog, Refractory Bed Materials, Mortars, Accosat 50, Magnesia Carbon Bricks, Magnesite Bricks, Silicon Carbide Bricks, Basic Ramming Mass, Chromite Sand, Magnesia Chrome Bricks, Acid Proof Bricks, Silica Ramming Mass, Insulation Bricks, Refractory Shapes and Well Block from Bardhaman.

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Size | 9x4.5x3 |

| Type | High Alumina Bricks, Bricks |

| Material | Alumina |

| Shape | Rectangular, Square, As Per Use |

| Application | In Kilns And Furnaces |

| Color | Brown, Creamy, Yellow, Light Brown |

| Texture | Solid |

| . Resistance Durability | Heat Resistance |

| Brand Name | KS-HA |

| SiO2 Content (%) | 30-60 |

| Al2O3 Content (%) | 40-70 |

| Refractoriness (Degree) | 1450 |

| Colour | Brown |

| Usage | Furnace and Kilns |

| MOQ | 10 MT |

| Iron | As per use |

| Product Code | KS-HA |

| Port | Kolkata |

| Payment Terms | L/C, T/T, Other |

| Delivery Time | 45 Days |

| Packaging Details | As per Requirement |

Preferred Buyer From

| Location | Worldwide |

We offer a wide range of High Alumina Bricks that are extensively used in different industries. Our High Alumina Bricks and Fireclay range is available in different varieties/shapes as per the specifications given by the clients. We provide High Alumina Bricks that are highly resistant and durable without causing any environmental hazards maintaining High standards are made from a variety of raw materials having different properties. Shapes of the High Alumina Bricks are made as per the drawings and measurements provided by the clients and only high grade fireclay and raw materials are used in their manufacturing.

Methods of Preparation :

- Dry pressing

- Firing in high temperature ceramic kilns

Types :

- MHD/HHD Bricks :

- General-purpose firebricks with 30% -34% / 38%-40% Alumina content

- Manufactured with selected grades of calcined fire clay

- Fired as per the requisite applications

- Shapes as per users requirement

- Superduty Bricks :

- 42-45 % Alumina content; a combination of high grade calcined clays and calcined kainite Kyanite.

- Very pure, low porosity bricks

- Exceptional hot strength

- Shapes as per users requirement

- Suitable for : Glass regenerator and Iron making applications

- Bauxite Based Bricks :

- Made using calcined indigenous/imported bauxite

- Highly economical

- Especially the 70% and 80% class, which give high performance

- Suitable for steel ladles and cement rotary kilns

- Shapes as per users requirement

- Sillimanite :

- Extra pure dense grades, high mullite content

- Suitable for glass plant, Blast furnace Stove and stack

- These are cost-effective, low iron alternative for Suitable for applications up to 17000C

Specialty :

- Conforming to IS standard

- Low iron content

- Highly Resistant to high temperatures

- Durable

- Pure and dense grades

Applications :

- Cement industry

- Steel industry

- Metal industry

- Foundries

- Glass industry

- Ceramics industry

- Power Plants

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Size | 9x4.5x3 And As Per Order |

| Type | Refractories |

| Material | Alumina |

| Shape | As Per Item |

| Certification | ISO9001:2008 |

| Application | In Kilns And Furnaces |

| Color | Brown, creamy |

| Structure | Solid |

| Resistance Durability | Heat Resistance |

| Usage | In kilns and furnaces |

| Product Name | Firebricks |

| Product Code | KS-FB |

| Port | Kolkata |

| Payment Terms | L/C, T/T, Other |

| Packaging Details | As per need |

Preferred Buyer From

| Location | Worldwide |

These are being used in different metallurgical industries. we have the best quality of firebricks.

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Type | Castables |

| Application | Boiler Work, Burner Blocks, Furnace, Refractory Material |

| Color | Black, Brown, Creamy, Off White, Grey |

| Feature | High Refractoriness |

| Condition | Good |

| Form | Powder |

| Packaging Type | Plastic Bag, Plastic Sacks |

| Packaging Size | 25 Kg, 50 Kg |

| Material | Alumina Dense |

| Al2O3 Content (%) | 45 TO 90 |

| Size | Grains |

| Density | 2.0g/cm3 |

| Fe2O3 | 1.2-3.5% |

| Purity | 100% |

| Storage life | 6 months |

| Name | KS-Cast |

| Product Code | KS-Cast |

| Port | Kolkata |

| Payment Terms | L/C, D/A, D/P, T/T, Other |

| Delivery Time | 1 Month |

| Packaging Details | As per Requirement |

Preferred Buyer From

| Location | Worldwide |

These are dry mix hydraulic compositions of graded refractory aggregates with a suitable bonding material, Fillers & (/or) special Additives. On addition of the prescribed quantity of water to these compositions, a wet concrete-like mass is produced which forms useful castables. Ceramic bond is developed when the same is fired at a certain high temperature.

Available Grades of Refractory Castables :

- Medium purity castables

- High Purity Dense Castables

- Low Cement Castables

- Insulating Castables

High Purity Dense Castables :

- Ideal for High Temperature applications

- Available in various grades with low iron content

- Used for a specific range of operational conditions

- Hydraulically set with easily mouldable and castable shapes

- Specifically designed for diverse combustion conditions

- Applicable for both back-up and furnace exposure

Medium Purity Castables :

- Ideal for Medium Temperature applications

- Used in oxidizing atmosphere

- Hydraulically set, with easily moldable shape

- Used in : Boiler work, general furnace, burner blocks etc.

Low Cement Castables :

- Low cement concentration

- Excellent physical properties

- Low porosity

- High strength

- Good abrasion resistance

- Ideal for

- Refractory abuses due to abrasion

- High temperature applications

Insulating Castables :

- Low densities are light

- Adequately strong and of low conductivity

- Serving as hot face or backup insulating refractory lining used in reduced conditions.

- Low to medium strength

- Tailored varieties are also supplied to customer’s requirements.

- Substitutes for varieties of imported castables.

Characteristics :

- Low thermal conductivity

- Superior quality

- Long functional life

- Easy to use

Applications :

- Steel industry

- Cement industry

- Foundries

- Sponge Iron

- Ceramics industry

- Non-Ferrous industry

- Power Plants

- Petrochemical

- Chemical Plants

- Rolling Mills

- Glass industry

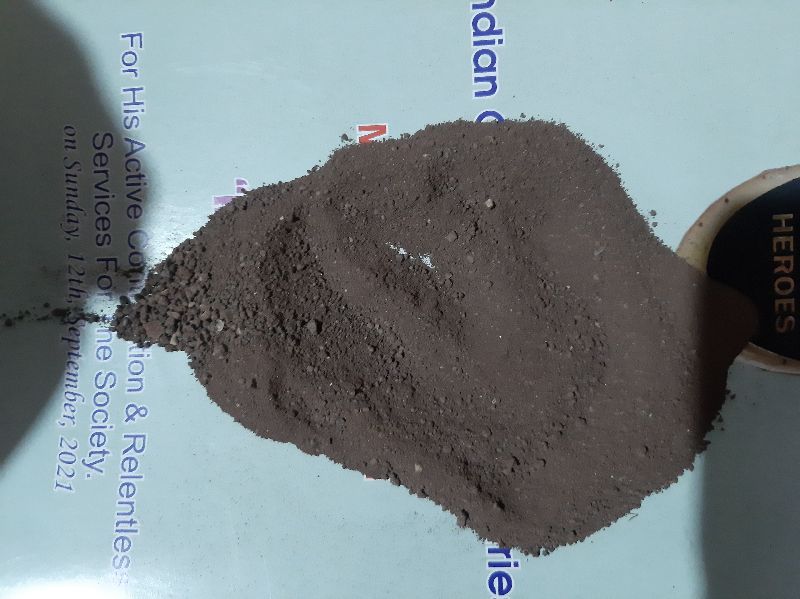

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Type | Refractories |

| Material | Clay |

| Shape | As Per Item |

| Color | As Per Product |

| Resistance Durability | Heat Resistant |

| Usage | Refractories |

| Product Name | Grog |

| Size | As per product |

| Product Code | KS-GG |

| Port | Kolkata |

| Payment Terms | L/C, T/T, Other |

| Delivery Time | 15 days |

| Packaging Details | As per usage |

Preferred Buyer From

| Location | Worldwide |

These are the rejected refractories which are being used by the Refractory Plants and different metallurgical purposes.

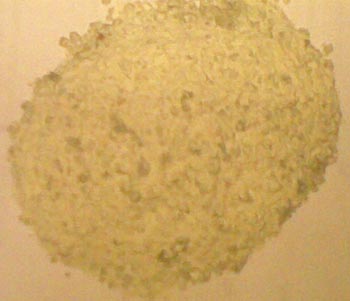

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Country of Origin | India |

| Size | 1-3 mm |

| Type | Bed Material |

| Material | Alumina |

| Shape | Grains |

| Application | Steel And Power Plants |

| Color | Brown, Red, Yellow |

| Structure | Solid |

| Resistance Durability | Heat Resistance |

| Brand Name | KS-BM |

| SiO2 Content (%) | 60 |

| Al2O3 Content (%) | 35 |

| Refractoriness (Degree) | 1450 |

| samples | NA |

| Packaging Type | Bags |

| State | Solid |

| Service Temperature | 1250 C |

| Fe2O3 | 2-3 % |

| Bulk Desity | 1050-1100 gm/cc |

| MOQ | 5 MT |

| Product Code | KS-BM |

| Port | Kolkata |

| Payment Terms | L/C, D/A, D/P, T/T, Other |

| Delivery Time | 30 Days |

| Packaging Details | As per Requirements |

Preferred Buyer From

| Location | Worldwide |

Our Bed Material is a highly demanded refractory material. The Fluidised Bed Material is manufactured as per the international recommended quality standards under the supervision of experienced and qualified persons ensuring customers satisfaction all the time, by offering them superlative quality of iron free bed material for Boilers. We further check the quality of procured material at our end, before dispatching it to the clients. We offer Bed material for both AFC Boiler as well as CFBC Boiler.

Demanded in :

- Steel industry

- Power Plants

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Country of Origin | India |

| Application | Jointing Of Bricks |

| Color | As per Product |

| Purity | As Per Product |

| Form | Powder, Dust |

| Packaging Size | 25kg |

| Usage | Jointing of Bricks |

| Product Name | Mortars |

| Size | Powder |

| MOQ | 2 MT |

| Product Code | KS-RM |

| Port | Kolkata |

| Payment Terms | L/C, T/T, Other |

| Delivery Time | immediate |

| Packaging Details | As per use |

Preferred Buyer From

| Location | Worldwide |

We provide a vast array of Mortars in different varieties, which is used for joining different types of bricks. Our Mortars is manufactured using high grades of fireclay and other materials, which greatly add to its strength and performance. The Mortars in powder form is sometimes supplied with liquid binder and the amount of this binder is used to achieve a trowelling consistency. We are known as a preeminent Mortars Exporter and Supplier from India due to the quality of our Mortars.

Attributes :

- High refractoriness

- Long service life

- High strength

- Excellent Plasticity

- Stable properties

- Highly resistant to extreme temperatures

- High Bonding strength

Applications :

- Steel industry

- Cement industry

- Ceramics industry

- Power Plants

- Petrochemical

- Chemical Plants

- Foundries

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Country of Origin | India |

| Type | Refractory Mortars |

| Material | Refractory Materials |

| Application | Laying of High Alumina Bricks |

| Grade | 100 Mesh |

| Color | White to Grey |

| Form | Powder |

| Packaging Size | 25-50kg |

| Brand Name | KS-A50 |

| Shape | Powder |

| SiO2 Content (%) | 40 |

| Al2O3 Content (%) | 50 |

| Refractoriness (Degree) | 1500 |

| Usage | Refractory Mortar |

| Product Code | KS-A50 |

| Port | Kolkata |

| Payment Terms | L/C, T/T |

| Delivery Time | 15 days |

| Packaging Details | 25-50 Kg New HDPE bags |

Preferred Buyer From

| Location | Worldwide |

These are the highly recommendable Mortars used as laying mortar for High Alumina Bricks.

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Size | as per use |

| Type | Magnesia Carbon Brick, Bricks |

| Material | Magnesia Carbon |

| Shape | Rectangular, Square, As Per Use |

| Application | Industrial Use |

| Color | Black |

| Structure | Solid |

| Resistance Durability | Heat Resistance |

| Certification | ISI Certified |

| Product Code | MgOC |

| Port | Kolkata |

| Payment Terms | L/C, T/T, Other |

| Delivery Time | 1 Month |

| Packaging Details | Export Packing |

Preferred Buyer From

| Location | Worldwide |

We are a reliable Importer and Supplier of MAG Carbon Bricks for Converter/ EAF /Ladle. The MAG Carbon Bricks for Converter/ EAF /Ladle that we bring to you is made up of top-notch quality raw materials and sophisticated machines.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Country of Origin | India |

| Size | As per order |

| Type | Magnesite Bricks |

| Material | Magnesite |

| Shape | As per use |

| Application | In Kilns and furnaces |

| Color | Brown |

| Structure | Solid |

| Resistance Durability | Heat Resistance |

| Product | Magnesite Bricks |

| Product Code | KS-MB |

| Port | Kolkata |

| Payment Terms | L/C, T/T, Other |

| Delivery Time | 30 Days |

| Packaging Details | As per order |

Preferred Buyer From

| Location | Worldwide |

Magnesite Bricks Mg0

The Magnesite brick is one of the most widely used basic refractory bricks.

Their main advantage is very high slag resistance to lime and iron rich slags. It is very important for steelmaking processes.Different grade magnesites used as raw materials produce Magnesia bricks of various qualities ( 85 % -95 %) . Synthetic magnesite and dead burnt magnesite, low in iron, boron and silica are used as raw materials for magnesite brick production

Magnesite refractory products have the properties of bearing high temperature, high refractoriness under load and good resistance to alkali. Magnesite refractory bricks are widely used in the basic zone of metallurgical furnaces, non-ferrous furnaces and regenerator of glass furnaces.

- Good resistance to basic slags

- Spalling resistance

- Strong abrasion and corrosion resistance

- High cold crushing strength

- Very strong and extremely durable

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Type | Silicon Carbide Brick |

| Material | Silicon Carbide |

| Shape | Brick Shape, Square, As Per Use |

| Thickness | As Per Need |

| Certification | ISI Certified |

| Length | As Per Need |

| Application | Manufacturing Unit |

| Grade | ISI |

| Color | Black |

| Feature | Corrosion Proof, Durable, Eco Friendly, Excellent Quality, Fine Finishing, High Strength, Perfect Shape |

| Condition | New |

| Surface Finishing | Good |

| Size | As Per Use |

| Brand Name | KS-SC |

| Product Code | KS-SC |

| Port | Kolkata |

| Payment Terms | L/C, D/A, D/P, T/T, Other |

| Delivery Time | 45 Days |

| Packaging Details | As per need |

Preferred Buyer From

| Location | Worldwide |

Silicon Carbide refractories are produced from silicon carbide, a raw material synthesized in a resistance-type electric furnace at temperature exceeding 2500°C, through the reaction of silica with carbon. They have a thermal conductivity ten times that of fireclay refractories, good corrosion and thermal shock resistance, and can be formed into complex shapes. They can withstand slag attack and flame erosion. This makes CUMIFRAC unusual even among advanced refractories and has given it wide uses.

Outstanding Features

- Extremely high thermal conductivity

- Very high hot strength

- High erosion and abrasion resistance, thermal shock resistance

- Chemical inertness

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Country of Origin | India |

| Type | Ramming Mass |

| Shelf Life | 1year |

| Moisture | 0-5% |

| Packaging Size | 25 Kg |

| Product Code | KS-BRM |

| Port | Kolkata |

| Payment Terms | T/T |

| Delivery Time | 15 days |

| Packaging Details | As per need |

Preferred Buyer From

| Location | Worldwide |

Ramming Mass used in induction furnace for Basic Lining

Product Description

An Induction furnace ramming material made from Dead Burnt Magnesite clinker in association with Special Binders. It is bonded with clays and other chemical binders to achieve the desired sintering characteristics.

Product Specification

MgO - 86% Min.

Size - 0-5mm

|

Brand Name |

MgO % |

Cr2O2 |

Sio2 |

A2O3 |

Cao |

Grading |

Application |

|

KS-RAM-85 |

85 |

- |

5-6 |

- |

- |

0-5mm |

Basic Ramming Mass for EAF Bottom and for Fitting |

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Country of Origin | India |

| Type | Chromite Sand |

| Application | Ramming Mass |

| Grade | 10/20 |

| Color | Black, Brown |

| Form | Crystal, Dust |

| Packaging Type | HDPE Bags |

| Packaging Size | 25kg |

| Brand Name | Ramming Mass |

| Shape | Grains |

| SiO2 Content (%) | 10 |

| MgO Content (%) | 86 |

| CrO Content (%) | 8 |

| Product Code | KS-RM |

| Port | Kolkata |

| Payment Terms | T/T |

| Delivery Time | 15 Days |

| Packaging Details | As per Need |

Preferred Buyer From

| Location | Worldwide |

An Induction furnace ramming material made from Dead Burnt Magnesite clinker in association with Chrome. Specially bonded with clays and other chemical binders to achieve the desired sintering characteristics. These are used in induction furnace for Basic Lining

This material is also designed for repairing the cracks and other erosion that occurs in the lining during usage. It possesses good workability and has no shrinkage upto 1650°C and has good erosion resisting properties. The chemical composition is similar to the ramming mass but the grading/ binder is different for good workability.

Product Specification

MgO - 70% min, Cr2O3 - 8min, SiO2 - 8%max, CaO - 2% max

Sieve Distribution 0-1 and 0-2 mm

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Country of Origin | India |

| Size | As Per Need |

| Type | Magnesia Chrome Brick |

| Material | Magnesia Chrome |

| Shape | As Per Order |

| Application | Industrial Use |

| Color | Deep Brown |

| Structure | Solid |

| Resistance Durability | Heat Resistance |

| Brand Name | KS-MC |

| MgO Content (%) | 72 |

| CrO Content (%) | 8 |

| Product | Magnesia Chrome Bricks |

| Product Code | KS-MC |

| Port | Kolkata |

| Payment Terms | L/C, T/T, Other |

| Delivery Time | 30 Days |

| Packaging Details | As per order |

Preferred Buyer From

| Location | Worldwide |

Magnesia Chrome Bricks

Magnesia chromes bricks are mostly commonly used in cement kilns and non-ferrous furnaces. Magnesite chrome brick comprise of magnesium oxide (MgO) and chromium oxide (Cr2O3) as the main ingredient, periclase and spinel as main mineral components of refractory products.

Magnesite Chrome Refractory Bricks are produced from sintered magnesia and chrome ore by sintering at high temperature. Magnesite Chrome Refractory Bricks have high bulk density and advantages of stronger thermal resistance.

Magnesite Chrome Refractory Bricks are widely used for;

- Cement rotary kilns

- Glass kiln regenerators

- Permanent lining of steel furnaces

- Permanent lining of refining ladles

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Size | As per order |

| Type | Acid Proof Bricks, Bricks |

| Material | Clay |

| Shape | Rectangular |

| Thickness | 0-25mm, 25-50mm, 50-75mm |

| Application | Construction Use, Floor, Partition Walls |

| Color | Yellowish White |

| Structure | Solid |

| Resistance Durability | Heat Resistance |

| Usage | In Kiln and Furnaces |

| Product Code | KSAP |

| Port | Kolkata |

| Payment Terms | L/C, D/A, D/P, T/T |

| Delivery Time | 45 Days |

| Packaging Details | As Per Requirement |

Preferred Buyer From

| Location | Worldwide |

Acid Proof Bricks are highly useful in a variety of industries and offer superb protection even in hazardous areas. Acid Proof Bricks are manufactured using a mixture of different Clay and feldspar due to which they have varying properties. Acid proof Bricks are manufactured by dry pressing method and firing in high temperature ceramic Kilns. Since these are manufactured from a mixture of different raw materials, the properties are subject to variations as the raw material themselves may vary. The properties shown are mean values from quality control figures conforming to IS 4860.

These bricks are highly demanded in the national and international markets. We stock bulk quantities of Acid Proof Bricks to be delivered at short notice to the clients.

Sizes :

- 230x115x75 mm

- 230x115x38 mm

- According to users requirement as per order

Specialty :

- High resistance to chemical attacks

- Low hygroscopic property

- Resistance to oxidization

- Resistant to corrosion and abrasion

- High strength with low crackling tendency

- High thermal Shock Resistance

Used in :

- Thermal Power Plant chimney

- Acid storage tanks

- Acid Digesters

- Sewage conduits

- Smelting furnaces

- Electroplating rooms

- Laboratories

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Type | Ramming Mass |

| Material | Silica |

| Shelf Life | 1year |

| Color | Snow White |

| Packaging Type | Plastic Packets |

| Moisture | 0-5% |

| Packaging Size | 25 Kg, 50 Kg |

| Usage | In Furnaces |

| Product Name | Silica Ramming Mass |

| Product Code | KS-SM |

| Port | Kolkata |

| Payment Terms | L/C, D/A, D/P, T/T, Other |

| Delivery Time | 30 Days |

| Packaging Details | In HDPE bags |

Preferred Buyer From

| Location | Worldwide |

We provide superior quality Silica Ramming Mass in special compositions as per the specifications of the customers. Silica Ramming Mass is mainly required in various industries for lining of induction furnaces. We offer different grades of Silica Ramming Mass material that are highly demanded because of their low iron content. We provide customized mixtures of the different grades as per the size and use of the furnace where they will be applied.

We have two types of Silica Ramming Mass :

- Quartzite Based Silica Ramming Mass

- Quartz Base Silica Ramming Mass

Characteristics :

- High refractoriness

- Minimum structural changes at high temperatures

- Free from moisture

- Free from impurities

- Highly resistant to corrosion

Applications :

- Ceramics industry

- Steel industry

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Size | 9x4.5x3 |

| Type | Insulation Bricks |

| Material | Clay |

| Shape | As per order |

| Application | In Kilns and furnaces |

| Color | White |

| Structure | Solid |

| Resistance Durability | Heat Resistance |

| Brand Name | KS-IB |

| Al2O3 Content (%) | 35 |

| Usage | Kiln ad Furnaces |

| Product Name | Insulating Bricks |

| Product Code | KS-IB |

| Port | Kolkata |

| Payment Terms | L/C, T/T, Other |

| Delivery Time | 30 Days |

| Packaging Details | As per Order |

Preferred Buyer From

| Location | Worldwide |

These products are specific and is being used for various purposes in steel plants and different other industries.

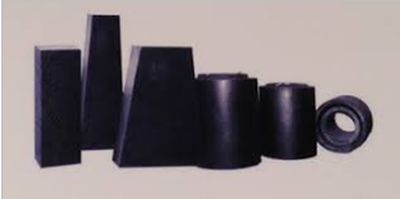

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Country of Origin | India |

| Size | As per need |

| Type | Refractory Shapes |

| Material | Alumina |

| Shape | As Per Item |

| Application | As Per Product |

| Color | Brown |

| Structure | Solid |

| Resistance Durability | Heat Resistance |

| Brand Name | KS-RS |

| SiO2 Content (%) | 30-60 |

| Al2O3 Content (%) | 40-70 |

| Grade | HIgh Alumina |

| Dimensions | Specific |

| Thickness | As per need |

| Product Code | KS-RS |

| Port | Kolkata |

| Payment Terms | L/C, T/T, Other |

| Delivery Time | 45 Days |

| Packaging Details | As per need |

Preferred Buyer From

| Location | Worldwide |

Refractory shapes are made for specific need of the user with specific purposes . These are of different shapes ,sizes and specifications and for use in furnaces, ovens, kilns, and boilers.

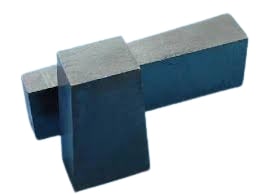

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Size | 4.5 inchx4.5 inchx3 inch |

| Type | Refractory Well Block |

| Material | Alumina |

| Shape | Square |

| Color | Brown |

| Structure | Solid |

| Resistance Durability | Heat Resistance |

| Usage | Refractory |

| Product Code | KS-WB |

| Port | Kolkata |

| Payment Terms | L/C, T/T, Other |

| Delivery Time | 45 Days |

| Packaging Details | As per need |

Preferred Buyer From

| Location | Worldwide |

These are being used in steel plants . catering to the industries of local and Bangladesh , we have best quality of product.